Air Fuel Ratio in Gas Turbine Formula

Gamma is just a number that depends on the gas. The steam turbine is used as a section of stationary and transport steam turbine power plants.

Chapter 11 Combustion Updated 5 31 10

The percentage of theoretical air used during this process.

. Air standard cycle Actual cycle. Besides turbine units the power plants include boilers as the units to generate steam steam condensers and other equipment. The core of the eCatalog are CHP Packagers who commit to provide pre-engineered and tested Packaged CHP systems that meet or exceed DOE.

Specific heat of air is constant. Solid Oxide Fuel Cells. One mole of C3H8 is burned with an unknown amount of air during a combustion process.

Solid oxide fuel cells are manufactured of a thin layer of ceramics. So if the pressure doubled the temperature ratio is 1. The Packaged Combined Heat and Power Catalog eCatalog is a voluntary publicprivate partnership designed to increase deployment of CHP in commercial institutional and multi-family buildings and manufacturing plants.

Because of two factors the total Steam Turbine Efficiency is fairly low about 29. Combustion or burning is a high-temperature exothermic redox chemical reaction between a fuel the reductant and an oxidant usually atmospheric oxygen that produces oxidized often gaseous products in a mixture termed as smokeCombustion does not always result in fire because a flame is only visible when substances undergoing combustion vaporize but when. Processes are non-flow processes.

The basic operation of the gas turbine is a Brayton cycle with air as the working fluid. Air behaves as the ideal gas. Why Is Steam Turbine Efficiency So Low.

An analysis of the combustion products shows that the combustion is complete and there 3 moles of free O2 in the products. Working fluid does not always behave like an ideal gas. The equivalence ratio c.

For air at standard conditions it is 14. Working fluid flows. And provided that definitions within any subsequent.

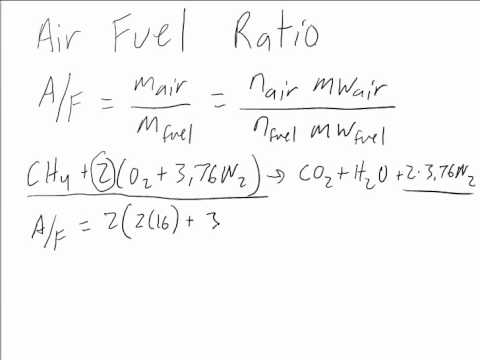

Subject 391-3-1 AIR QUALITY CONTROL Rule 391-3-1-01 Definitions. Energy is then added by spraying fuel into the air and igniting it so that the combustion generates a high-temperature flow. The AFR calculator air-fuel ratio will give you the rate of air to fuel and the mass of air needed for its complete combustion.

The ceramics in SOFCs are not electrically and ionically active until they are in the range of 500-1000 o C 1060-2120 o F. Keep reading to learn about what is the air-fuel. A mixture of air and fuel is a working fluid.

Air is working fluid. The value of 1 - 1gamma is about 286. This high-temperature pressurized gas enters a turbine producing a shaft.

The actual air-fuel ration b. Includes energy and materials balances commercial engineering cost breakdown and pilot plant data. When CO2 is delivered at 15 MPa the design requires either 881 GJ of.

First direct air capture paper for which all major components are either drawn from well-established commercial heritage or described in sufficient detail to allow assessment by third parties. Unless a different meaning is required by the context the following terms as used in these rules shall have the meaning hereinafter respectively ascribed except that to the extent terms are not defined in these rules the Acts definitions control. During the compression process as the pressure is increased from p1 to p2 the temperature increases from T1 to T2 according to this exponential equation.

The high temperature enables them to oxidize almost any fuel including gasoline natural gas diesel biofuels hydrogen and even coal gas. Specific heats are variable with respect to temperature. Atmospheric air flows through the compressor that brings it to higher pressure.

Combustion is a process found in different technologies such as heating devices internal combustion engines gas turbines rocket engines etc where AFR is an important parameter.

Work Ratio And Air Rate For Gas Turbine Youtube

Effect Of Ambient Temperature And Air Fuel Ratio On Thermal Efficiency Download Scientific Diagram

Afr Calculator Air Fuel Ratio Calculator

Comments

Post a Comment